Global Conductive Ink Market By Product (Dielectric Ink and Conductive Silver Ink), By Application (Membrane Switches, Photovoltaic, Automotive, and Displays), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2022-2032

- Published date: Dec 2021

- Report ID: 67457

- Number of Pages: 374

- Format:

- keyboard_arrow_up

Conductive Ink Market Overview:

The market size for conductive ink worldwide was USD 3,912.73 million in 2021. It is projected to grow at a CAGR of 4.3% during the forecast period.

Consumer electronics, as well as the growing demand for cleaner energy, have fueled the market. The industry is expected to expand over the forecast period. It will replace bulky circuits, as well as energy-consuming wires, in the coming years.

Global Conductive Ink Market:

Product Analysis

The global revenue for conductive silver ink reached over 22% in 2021. This is because it is widely used for its excellent conductivity and durability as well as thermal stability and reliability. While silver-based inks have seen a rise in their prices, manufacturers are choosing to make products with minimal silver. The conductive ink can be made with graphene or carbon base, which provides it with more flexibility and performance. Nanomaterials are made with carbon-based inks. Because of their flexibility and low cost, they are often used in complex devices such as touch screens and sensors.

These materials are used in contact pad manufacturing. They can also be found in remote control, mobile phones, printed circuit boards, and printed circuit board applications. Because of the increased use of dielectric inks for injection-molded electronics (IME), the dielectric ink market is expected to grow significantly over the forecast period. IME is used in integrating flexible circuits into three-dimensional products.

These circuit boards are also used in electronic devices such as washing machines, automobile consoles, and steering wheels. Because of its increased use in screen printing, the segment of conductive polymers is expected to grow at a CAGR of 3.6% in volume. However, screen printing, one of the oldest printing technologies, is in rapid decline and is likely not to be used in the future, which will negatively impact segment growth.

Application Analysis

In the production of photovoltaic fabrics, conductive inks are used. The growth of the photovoltaic sector is expected to be driven by the rising popularity of clean energy over the forecast period. The key driver for solar plants worldwide is the expected increase in electrical demand. Photovoltaics will be in high demand in countries such as China and India.

Conductive ink is a widely-used product in the automotive sector. It accounted for 15.3% of total market revenues in 2021. The growth rate of this application segment has been nearly constant in recent times. Ink traces and rear windows are two areas where innovation is possible. This could lead to market growth.

Smart packaging applications also use conductive inks. They protect against counterfeits and determine shelf life. Additionally, they track details of importers as well as exporters. Smart packaging often called active or intelligent packaging, has gained popularity in the pharmaceutical industry and food product industries. This is expected to drive the FMCG sector’s growth in the conductive ink market.

Over the forecast period, there will be a steady demand for conductive ink from the displays market. As it has excellent electrical conductivity, conductive ink is expected to continue being used in electronic devices’ displays. Over the next period, research continues to be done to increase the effectiveness of conductive ink for displays.

Key Market Segments:

Product

- Dielectric Ink

- Conductive Silver Ink

Application

- Membrane Switches

- Photovoltaic

- Automotive

- Displays

Market Dynamics:

Rising concerns over high carbon dioxide emissions have prompted government agencies to consider low carbon alternatives. This has created increased investment opportunities for solar PV systems which will increase product demand over the forecast time. Due to its high thermal conductivity as well as printability, the conductive silver ink is used widely in many applications. Manufacturers are now looking for alternatives to silver because of its high cost and scarcity. Therefore, copper has been identified as an excellent alternative to silver. It is low-cost and has high electrical conductivity.

Some conductive inks include polymeric conduction substances. These inks offer a cost-effective way to create modern conductive traces, as opposed to traditional methods such as copperplate substrates or etching copper. The main driving force behind the market is the rising demand for smaller and more efficient consumer electronics. This product can replace traditional wire circuits because of its smaller size and higher energy efficiency.

It also has better durability. These products also offer greater durability, reliability, energy efficiency, and energy savings in portable devices. Conductive ink is also used in fuel cells, batteries, and other applications. The demand for this product will increase over the forecast period. Research efforts are underway to create cheaper raw material types such as graphene and carbon, which have similar properties to silver. Both government and companies are looking to find new uses for conductive inks. This will also help the global market during the forecast period.

Smart packaging is a type of packaging that extends shelf life, displays information clearly, and makes it easy to use. Smart labels are created using radio-frequency ID (RFID) methods. Conductive inks allow RFID manufacturing to be done faster, more efficiently, as well as being significantly cheaper. RFID reduces human errors and helps to prevent counterfeiting in packaging. This is a problem that was not possible with traditional techniques.

Consumer awareness is increasing, which has resulted in a rise in demand for smart packaging over the forecast period. This will in turn favor the growth of the conductive ink industry. Conductive inks are used in the production of readable displays that can be used with smart packaging.

Conductive inks exhibit superior conductivity, electron mobility, and low resistivity. They also have high chemical and thermal stability. These properties are important for conductive ink applications, such as RFID tag printing, circuit repairing, and PCB boards. You can adjust the size of conductive inks to suit the requirements of your application. Market growth is expected to be aided by the increasing demand for customization and favorable properties for conductive inks for electronic application needs.

Traditional methods for conductive circuit tracing are expensive compared to conductive inks. This is because it’s difficult to improvise or repair with conventional tracing. Conductive inks are easy to use and cost-effective. Conductive ink tracing produces minimal waste, which contributes to higher efficiency. These factors will all drive the conductive-ink market demand in the next eight years.

Due to their outstanding printability, conductibility and printability, silver inks have been increasingly used for electronic applications. Manufacturers have created alternative conductive solutions to silver inks due to the scarcity of raw materials and high prices. Because of its low cost, high electrical conductivity, and low cost, copper has been considered a viable alternative to silver. Because of these properties, manufacturers can lower the production costs for conductive inks.

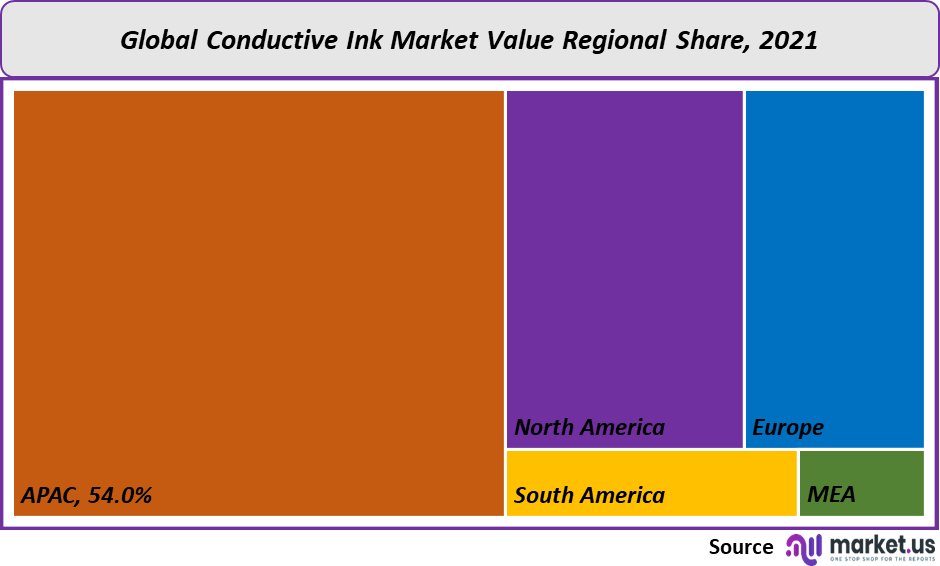

Regional Analysis:

Asia Pacific’s conductive ink industry dominated the global market, accounting for 54% of total market revenues in 2021. China and India were the largest conductive ink markets. The conductive inks market has seen an increase in investments made in India and China to establish solar photovoltaics. They are believed to produce enormous amounts of solar energy. This could lead to the substitution of non-renewable energy. The Asia Pacific region’s macroeconomic factors include the rapidly growing middle class, increasing disposable incomes, education, and changing demographics. The region has a high demand for conductive inks for electronics. Market growth will also be boosted by the presence of key players in the Asia Pacific.

The U.S. is second in automobile production worldwide and has seen high demand for conductive inks. The U.S. market has seen a large growth due to its high market size, mass-production capability, product variety as well as high disposable incomes. The country’s presence of global companies and their manufacturing hubs have also contributed to the rise of the conductive paint market.

Germany’s established industrial sectors include transportation, packaging, labeling, and plastic parts. The market’s overall growth will be affected by the expected growth in the key end-use markets for conductive inks. This is due to the country’s favorable industrialization environment and rapid increase in demand.

Key Regions and Countries covered іn thе rероrt:

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Russia

- Spain

- Rest of Europe

- APAC

- China

- Japan

- South Korea

- India

- Rest of Asia-Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- MEA

- GCC

- South Africa

- Israel

- Rest of MEA

Market Share Analysis:

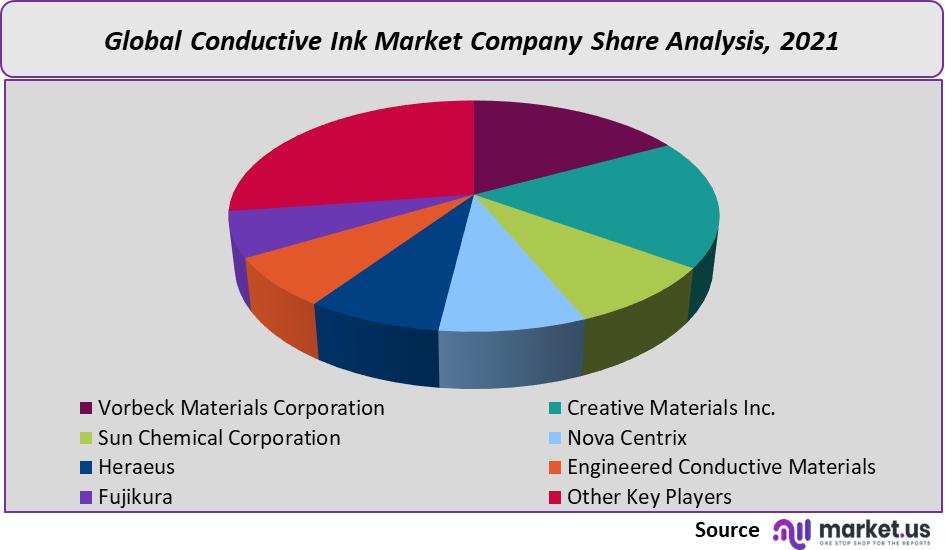

The global market for conductive ink is fragmented. Many companies from around the world participate and account for a significant portion of the overall market.

DuPont, Conductive Compounds Inc., and PPG Industries are forward-integrated across the value chain. These companies are involved both in product manufacturing and distribution for various applications. Because they are renewable energy sources, applications such as photovoltaics will drive market growth in the future. Henkel developed conductive inks with minimal silver content, named Henkel ECI 1001 E&C. They can be used in automotive sensor applications as cost-effective alternatives to conductive gold inks. The product is affordable, has a lower silver content, and performs the same as traditional conductive Silk inks.

Key Market Players:

- Vorbeck Materials Corporation

- Creative Materials Inc.

- Sun Chemical Corporation

- Nova Centrix

- Heraeus

- Engineered Conductive Materials

- Fujikura

- Other Key Players

For the Conductive Ink Market research study, the following years have been considered to estimate the market size:

Attribute Report Details Historical Years

2016-2020

Base Year

2021

Estimated Year

2022

Short Term Projection Year

2028

Projected Year

2023

Long Term Projection Year

2032

Report Coverage

Competitive Landscape, Revenue analysis, Company Share Analysis, Manufacturers Analysis, Volume by Manufacturers, Key Segments, Key company analysis, Market Trends, Distribution Channel, Market Dynamics, COVID-19 Impact Analysis, strategy for existing players to grab maximum market share, and more.

Regional Scope

North America, Europe, Asia-Pacific, South America, Middle East & Africa

Country Scope

United States, Canada and Mexico, Germany, France, UK, Russia and Italy, China, Japan, Korea, India and Southeast Asia, Brazil, Argentina, Colombia etc.Saudi Arabia, UAE, Egypt, Nigeria and South Africa

Frequently Asked Questions (FAQ)

Q: What is the size of the Conductive Ink market in 2021?The Conductive Ink market size is estimated to be US$ 3,912.73 million in 2021.

Q: What is the projected CAGR at which the Conductive Ink market is expected to grow at?The Conductive Ink market is expected to grow at a CAGR of 4.3% (2023-2032).

Q: List the segments encompassed in this report on the Conductive Ink market?Market.US has segmented the Conductive Ink market by geographic (North America, Europe, APAC, South America, and Middle East and Africa). By Product, market has been segmented into Dielectric Ink and Conductive Silver Ink. By Application, the market has been further divided into Membrane Switches, Photovoltaic, Automotive, and Displays.

Q: List the key industry players of the Conductive Ink market?Vorbeck Materials Corporation, Creative Materials Inc., Sun Chemical Corporation, Nova Centrix, Heraeus, Engineered Conductive Materials, Fujikura, and Other Key Players engaged in the Conductive Ink market.

Q: Which region is more appealing for vendors employed in the Conductive Ink market?Asia Pacific is accounted for the highest revenue share of 54%. Therefore, the Conductive Ink industry in Asia Pacific is expected to garner significant business opportunities over the forecast period.

Q: Name the key areas of business for Conductive Ink?Germany, France, China, India, Japan, and Brazil are key areas of operation for Conductive Ink Market.

Q: Which segment accounts for the greatest market share in the Conductive Ink industry?With respect to the Conductive Ink industry, vendors can expect to leverage greater prospective business opportunities through the conductive silver ink segment, as this area of interest accounts for the largest market share.

![Conductive Ink Market Conductive Ink Market]()

- Vorbeck Materials Corporation

- Creative Materials Inc.

- Sun Chemical Corporation

- Nova Centrix

- Heraeus

- Engineered Conductive Materials

- Fujikura

- Other Key Players

- settingsSettings

Our Clients

|

Single User

$5,999

$2,999

USD / per unit

save 50% |

Multi User

$7,999

$3,499

USD / per unit

save 55% |

Corporate User

$12,999

$4,499

USD / per unit

save 65% | |

|---|---|---|---|

| e-Access | |||

| Data Set (Excel) | |||

| Company Profile Library Access | |||

| Interactive Dashboard | |||

| Free Custumization | No | up to 10 hrs work | up to 30 hrs work |

| Accessibility | 1 User | 2-5 User | Unlimited |

| Analyst Support | up to 20 hrs | up to 40 hrs | up to 50 hrs |

| Benefit | Up to 20% off on next purchase | Up to 25% off on next purchase | Up to 30% off on next purchase |

| Buy Now ($ 2,999) | Buy Now ($ 3,499) | Buy Now ($ 4,499) |