Global Dental Laboratory Welders Market, by Type (Manual, Automatic), By Application (Cast Repairs, New Clasp Assembly,and Other Applications), and by Region and Companies Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2022-2032.

- Published date: Feb 2022

- Report ID: 84155

- Number of Pages: 341

- Format:

- keyboard_arrow_up

Dental Laboratory Welders Market Overview:

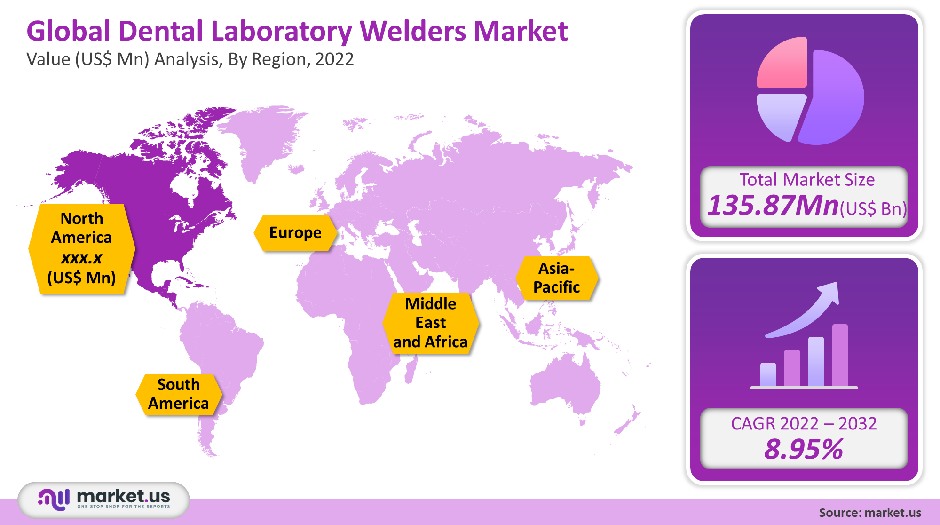

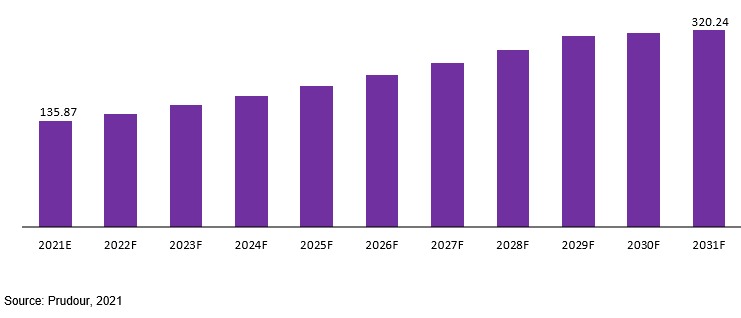

The global dental laboratory welders market is projected to reach a valuation of USD 320.24 Mn by 2031 at a CAGR of 8.95%, from USD 135.87 Mn in 2021.

Market.US announces the publication of a recently generated research report titled, “Global Dental Laboratory Welders Market, by Type (Manual, Automatic), By Application (Cast Repairs, New Clasp Assembly, Loops & Posts for Implants, Wrought Wire Single-Arm Clasping, Crown & Bridge Cases, Implant Restorations), and by Region – Global Forecast to 2031.” This report offers a holistic view of the global dental laboratory welders market through systematic segmentation that covers every aspect of this target market.

Dental laboratory welders are essential members of dental practice because they use specialized equipment and materials to help create prosthetic devices for patients. They work with a wide range of materials to fabricate metal appliances such as bridges, ceramic crowns, inlays, onlays, veneers, and dentures that are needed by dental patients. These technicians are often required to have a college degree or certificate of training for this profession. The job can be physically demanding and requires precision and attention to detail.

Dental laboratory welders are responsible for the intricate work of developing dentures, dental implants, and other prosthetic devices by joining together metal alloys with heat and pressure. The process of welding is primarily the melting of two or more pieces of metal into one. Welding falls under two categories: gas welding, which utilizes a gas flame to melt the metals; and electric arc welding, in which an electric current is used to create heat that melts the metals together.

Dental laboratory welders are known for using a welding torch to fix metal pieces together. Welding torches use a flame or an electric arc to heat metal so that it can be shaped or molded. This process is often used on the teeth of dentures, bridges, and crowns. A dental lab welder’s duties may also include operating various types of machinery, filing the teeth of dentures, and mixing certain metals needed for building dentures by hand.

These welders work with a variety of metals to create dental restorations for patients. They might be responsible for making bands to hold teeth in place, metal posts for crowns, or metal frames to hold bridges together. During their work, welders will need to use a gas-powered torch or solder to fuse thin sheets of metal to create a solid piece.

Global Dental Laboratory Welders Market Revenue (US$ Mn), 2021–2031

The need for dental laboratory welder professionals is significant as the incidence of various dental diseases and the need for oral care continues to rise, particularly among youngsters, as a result of increased sugary food intake, poor use of health services, and the adoption of inadequate oral hygiene measures.

For example, according to the Global Burden of Disease Study 2017, dental decay affects 60-90% of students and nearly 100% of adults worldwide, causing irritation and pain. As a result, the increasing number of dental care cases, in conjunction with surging consumer expenditures on healthcare, are paving the way for the dental treatment market, which in turn is anticipated to gradually drive up the demand for dental laboratory welding professionals and equipment around the world.

This market is expected to surge over the next decade owing to technological advancements in traditional welding processes such as soldering and brazing. According to the National Center for Biotechnology Information, laser welding procedures are proving to be an excellent way of combining metals in dentistry.

Laser welding is also said to improve biocompatibility and facilitate a corrosion-free prosthesis in the orofacial area. Furthermore, laser welding has advantages such as high mechanical strength, and the narrowing of heat-affected zones, which results in less distortion, a lower potential of contamination, shorter processing time, and corrosion-resistant joints. These kinds of advancements are anticipated to further augment this market.

The goal of laser welding is to achieve orofacial biocompatibility, while also providing a corrosion-free prosthesis. Aside from that, laser welding has several advantages, including excellent mechanical strength, lower contamination risk, and a shorter processing time. As a result, it will have a significant impact on the market dynamics for dental laboratory welders over the forecast period.

The global laboratory welders market was negatively impacted by the COVID-19 pandemic. Medical device manufacturers, suppliers, and logistics companies initially experienced substantial disruptions to their respective operations, which led to product deliveries being hindered, if not entirely halted. For the purchase of raw materials, essential components, and complicated finished medical goods, most healthcare organizations relied to a large extent on China.

The ongoing spread of this virus across the world had resulted in the imposition of trade restrictions on the deliveries of necessary goods. As a result, certain market players experienced discrepancies in medical device production and a slower-than-normal growth during the initial onset of the COVID-19 crisis, indicating a recent decline in the valuation of the dental laboratory welders market.

Various dental practices have had to bear challenges related to the dental laboratory welding occupation such as the temporary halting of their operations and job cuts as a direct result of the same. Another concern is that there is a certain lack of skilled professionals in this field, as well as a lack of adequate training programs for welders.

Dental laboratories, particularly in the United States, are becoming a popular business venture. Increasingly, individuals with a background in dentistry are looking to purchase equipment and open dental laboratories to provide high-quality, affordable procedures to the public. An essential skill required for this profession is welding, which is an intricate art form that requires dedicated training.

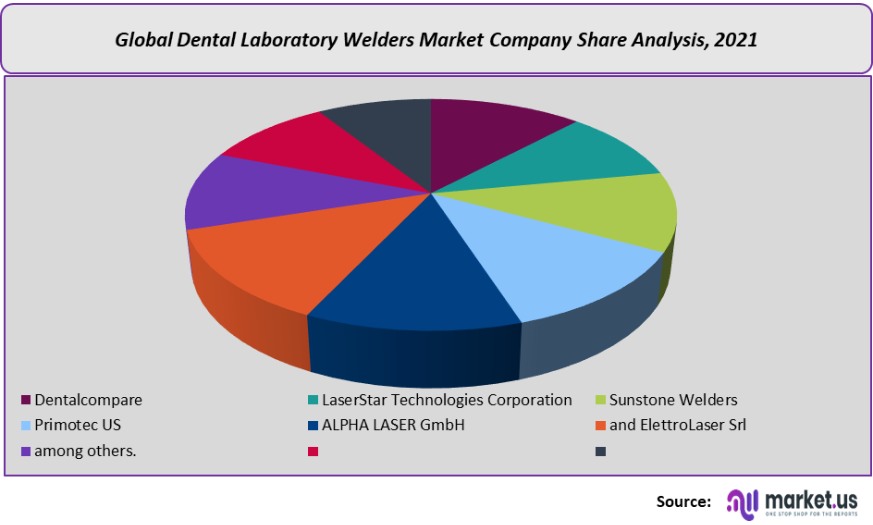

This research report on the global dental laboratory welders market includes major company profiles such as

- Dentalcompare

- LaserStar Technologies Corporation

- Sunstone Welders

- Primotec US

- ALPHA LASER GmbH

- and ElettroLaser Srl

- among others.

The Global Dental Laboratory Welders Market Segmentation is Based on Type, Application, and Region

Based on Type

- Manual

- Automatic

Based on Application

- Cast Repairs

- New Clasp Assembly

- Loops & Posts for Implants

- Wrought Wire Single-Arm Clasping

- Crown & Bridge Cases

- Implant Restorations

Based on Region

- North America

- Europe

- Asia-Pacific

- South America

- Middle East & Africa

![Dental Laboratory Welders Market Dental Laboratory Welders Market]() Dental Laboratory Welders MarketPublished date: Feb 2022add_shopping_cartBuy Now get_appDownload Sample

Dental Laboratory Welders MarketPublished date: Feb 2022add_shopping_cartBuy Now get_appDownload Sample - Dentalcompare

- LaserStar Technologies Corporation

- Sunstone Welders

- Primotec US

- ALPHA LASER GmbH

- and ElettroLaser Srl

- among others.

- settingsSettings

Our Clients

|

Single User

$5,999

$2,999

USD / per unit

save 50% |

Multi User

$7,999

$3,499

USD / per unit

save 55% |

Corporate User

$12,999

$4,499

USD / per unit

save 65% | |

|---|---|---|---|

| e-Access | |||

| Data Set (Excel) | |||

| Company Profile Library Access | |||

| Interactive Dashboard | |||

| Free Custumization | No | up to 10 hrs work | up to 30 hrs work |

| Accessibility | 1 User | 2-5 User | Unlimited |

| Analyst Support | up to 20 hrs | up to 40 hrs | up to 50 hrs |

| Benefit | Up to 20% off on next purchase | Up to 25% off on next purchase | Up to 30% off on next purchase |

| Buy Now ($ 2,999) | Buy Now ($ 3,499) | Buy Now ($ 4,499) |