Global Machine Tools Market By Type (Machining Centers, Turning Machines, Grinding Machines, and Electrical Discharge Machines), By Application (Machinery Manufacturing, Automobile, and Aerospace & Defense), By Region, and Key Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2019-2028

- Published date: Aug 2022

- Report ID: 35729

- Number of Pages: 219

- Format:

- keyboard_arrow_up

Machine Tools Market Overview

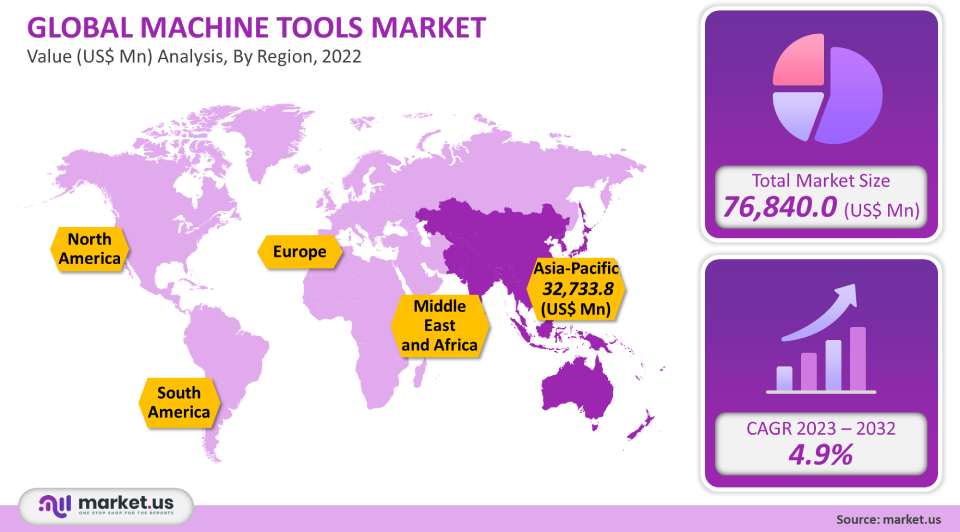

The global market for machine tools was estimated to be valued at US$ 76.84 billion in 2021 and is anticipated to grow at a CAGR of 4.9% over the forecast period. The key factors propelling the sector are technological advancements in machine tools, including multi-axis arms and robotics, as well as the rise in the manufacturing industry. In 2020, the COVID-19 pandemic had an adverse influence on the global economy across all industry sectors. This crisis is also causing problems for machine tool manufacturers, which have had to slow down both production volumes and sales. Following the onset of this pandemic, the demand for digital services increased, and this changed the requirements for supply chains.

Global Machine Tools Market Scope:

Type Analysis

In 2021, with more than 75.60% of all sales, the ‘Metal Cutting Type’ sector accounted for the largest market share. In the ‘Metal Cutting’ segment, the ‘Turning machine tools’ sub-segment represented a sizeable portion of the market revenue share in 2021. It is anticipated that the demand for these tools will increase since machine tools can be used to produce a wide range of components, including crankshafts, nuts, wooden bowls, train parts, bolts, sleeves, and pump parts, among others. A typical production method used in machine shops and industries to produce high-precision goods and parts in a variety of shapes and sizes is milling machining.

Due to advantages like fewer human errors, high precision, and the capacity to produce individual components in small or large batches, milling machines are expected to become a greater necessity. Over the forecast period, the market for metal forming machines is anticipated to expand at a considerable CAGR. The aerospace, automotive, appliance, energy, construction, metal building products, and electronics industry, among others all employ metal forming equipment. Manufacturers of metal forming machines include Corrugated Metals Inc., Paramount Roll & Forming Inc., and PMF Industries Inc. Shearing, bending, pressing, shaping, and forming are a few of the processes that require metal forming equipment. This segment is anticipated to be driven by the use of press brake equipment. This is a result of the extensive use of sheet-bending, press brake metal forming equipment in sectors like agriculture, shipbuilding, transportation, aerospace, and oil & gas machinery.

Technology Analysis

The market category for computerized numerical control machines, which accounted for the highest revenue share globally in 2021, generated more than 84.3% of that sum. A greater need for more precision and efficiency in complex machining products, as well as decreased operational expenses in industries like aerospace, automotive, and defense, can all be attributable to an increase in the use of CNC machines. A number of interconnected Programmable Logic Controller (PLC) drives, sensors, and controllers make up the automated control system for CNC machines. Due to a surge in the demand for shorter lead times and higher precision outcomes, this sector is slated to be bolstered by the increasing automation of production processes over the forecast period.

The accuracy of a CNC machine ensures consistent product quality and increases manufacturing market growth rates. Demand has grown substantially, especially for CNC machines, due to strong expectations for productivity gains from manufacturing companies and the expansion of the industrial sector as a whole. Traditional machines are more in demand in bulk production industries including paper, textiles, and pharmaceuticals due to their low initial cost, simplicity of setup, and versatility to process a variety of materials. Drilling machines, milling, lathes, boring machines, and other sharp-cutting instruments are examples of machine tools that must be managed and steered by a human operator in traditional machinery. Conventional machine tools are frequently less expensive and used for jobs with lower production volumes. The need for conventional methods is, however, declining due to a lack of a qualified workforce.

End-Use Analysis

This market was led by the automotive end-use category, which in 2021 accounted for the highest revenue share of about 41.6% globally. The employment of numerous machine tools in the automotive industry is contributing to the growth of the automotive segment. In the automotive industry, milling machines are frequently used to make components including engine locks, gearbox cases, piston rods, and wheels. A significant end-user of machine tool products is the aviation industry. The aerospace machinery industry works hard to boost flight safety, decrease potential environmental harm, and raise the efficiency of producing aircraft components.

It is anticipated that the aerospace sector’s growing demand for cutting-edge materials, such as nickel alloys and titanium alloys, will encourage the use of these goods even more. Metalworking includes production processes that result in tools and petroleum machinery for the industrial sector and parts for other related sectors including mining, agriculture, construction, etc. The increasing utilization of these goods in the metalworking industry is likely to augment this category’s expansion over the forecast period. Manufacturers of hydropower turbines and generators frequently employ multi-axis systems, which is advancing the sector. For instance, 16-foot-diameter Francis and Pelton hydroelectric turbines can be produced by Canyon Industries Inc. using a 7-axis CNC milling machine.

Key Market Segments:

Metal Cutting

Metal Forming

By Technology

Conventional

CNC

By End-use

Automotive

Metal Working

Mechanical Engineering

Electrical industry

Aerospace

Other End-Uses

Market Dynamics:

Machine tools are used for shearing, drilling, grinding, cutting, and other types of deformation when shaping or machining metal and other hard materials. A number of tools are used in conjunction with machine tools to perform cutting and other deformation operations. In addition to providing guided motion for pieces, all machine tools also include some means of restricting a workpiece. Currently, machine tools are not powered by human muscles but by electricity or hydraulics. The manufacturers of machine tools aim to focus on creating products that require less maintenance. There are two types of machine tools: conventional and CNC. Nowadays, CNC machine tools are mostly used by end users due to their high productivity, high efficiency, and high precision. These products use numerical control, which aids in the production of uniform products. In order to abrade, mold, grind, sculpt, cut, drill, and nibble metal or other hard materials. They also help to increase total productivity while decreasing the quantity of human work required. The market for metal-forming machine tool market in the US has primarily been driven by the defense, aerospace, and automotive industries because of the high demand for fabricated metal products in these sectors. Therefore, during the course of the projected timeline, product demand is anticipated to be driven by the growth of these aforementioned industries.

The increase in demand for Electric Vehicles (EVs), self-driving cars, and trucks are contributing to a spike in the use of these items. The market is also driven by a growing need for fabricated metals in the United States. The demand for these products is then expected to increase over the forecast period as a result. This industry is being influenced by the Industry 4.0 movement to become a part of smart systems as it gains traction in the manufacturing sector. By decreasing idle time, Industry 4.0 has the potential to improve the usage of the machine tool industry in manufacturing operations, which is projected to increase the demand for these products over the forecast period.

A growth in additive manufacturing is also driving this market. Additive manufacturing is being used more frequently as organizations switch to quick and efficient production methods. The market is also expected to increase as a result of the growing need for production techniques for heterogeneous materials. The activities of CNC manufacturers will implement additive manufacturing. In the future, Okuma, for instance, plans to introduce its Laser EX machines, which will enable self-cooling, laser hardening for materials made of carbon steel, as well as heating by laser emission. As a result, future market growth is predicted to be favored by such creative technological combinations.

This market is presently being impacted by changes in the state of the global economy. Sales of these instruments are closely linked to manufacturing industry expenditures. As a result, it is projected that a downturn in the world economy will directly affect the revenue earned by the machine tools industry. Trends in the vehicle industry have also had a stronger impact on the tools sector due to the substantial use of machines in the industry. However, capital spending patterns in the automobile industry have a big impact on anticipated market revenues. Unexpected changes in a country’s political, social, or economic circumstances may also have an impact on how the market’s income is generated.

Regional Analysis

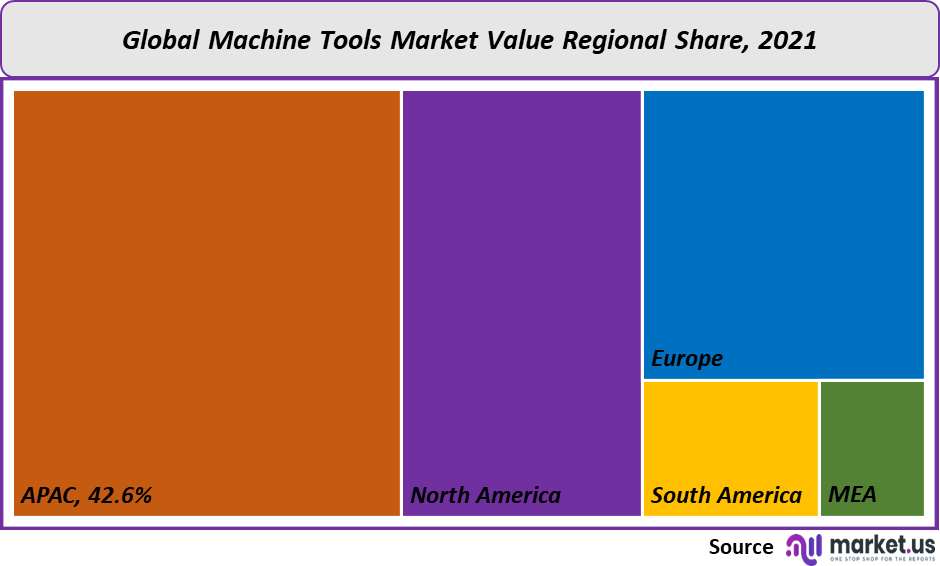

In 2021, the Asia Pacific region accounted for the highest percentage of global market revenue share at 42.6%. This region’s growth may be attributed to the increasing demand for these products in India in particularly industries like construction, manufacturing, and the automotive sectors. This region’s expansion is also being aided by current government initiatives such as “Make in India,” which local governments are seeking to leverage to encourage the domestic manufacturing sector.

A growing manufacturing sector, notably in transportation, equipment, and other industries, is anticipated to lead to an increase in the demand for this product in the Asia Pacific region. Due to an ongoing trend toward higher-value items, machining centers are likely to contribute to the regional market’s expansion over the anticipated timeline. Due to surging product demand in sectors like aerospace & defense, automotive, and oil & energy, this market in North America is also anticipated to expand at a high CAGR over the forecast period. The European Environment Agency estimates that in 2020, the sale of electric cars and vans will increase significantly. Therefore, it is anticipated that greater EV sector investments will benefit the electric car market, thereby boosting product demand in the process.

Key Regions and Countries Covered in this Report:

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Russia

Spain

Rest of Europe

APAC

China

Japan

South Korea

India

Rest of Asia-Pacific

South America

Brazil

Argentina

Rest of South America

MEA

GCC

South Africa

Israel

Rest of MEA

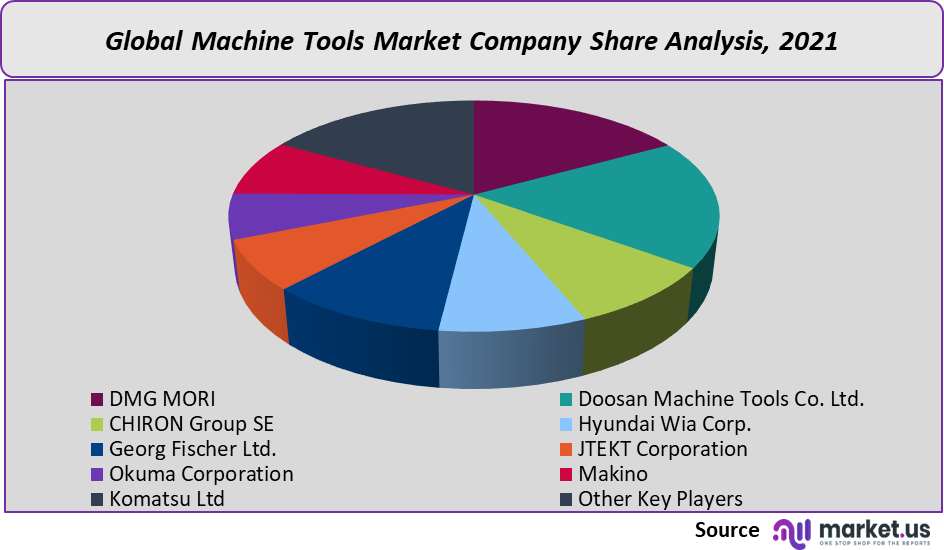

Market Share & Key Players Analysis:

To improve market penetration and to meet shifting technological advancements demands from various applications, such as the automotive, metalworking, electrical, and aerospace industry, among others, manufacturers are pursuing a number of strategies, including acquisitions, mergers, joint ventures, new product developments, and geographic expansions. COVID-19 hindered this industry’s growth and limited sales operations across a number of global locations, costing product manufacturers money. The early pandemic lockdowns, which ranged in severity, prevented or temporarily halted the transportation of finished goods and raw materials, thus adversely influencing the world’s manufacturing industry.

Market Key Players:

The following companies are some of the major players in the worldwide machine tools market:

CHIRON Group SE

Hyundai Wia Corp.

Georg Fischer Ltd.

JTEKT Corporation

Okuma Corporation

Makino

Komatsu Ltd.

Other Key Players

For the Machine Tools Market research study, the following years have been considered to estimate the market size:

Attribute Report Details Market Size in 2022

76.84 Billion

Growth Rate

4.9%

Forecast Value in 2032

130.05 Billion

Historical Years

2016-2020

Base Year

2021

Estimated Year

2022

Short Term Projection Year

2028

Projected Year

2023

Long Term Projection Year

2032

Report Coverage

Competitive Landscape, Revenue analysis, Company Share Analysis, Manufacturers Analysis, Volume by Manufacturers, Key Segments, Key company analysis, Market Trends, Distribution Channel, Market Dynamics, COVID-19 Impact Analysis, strategy for existing players to grab maximum market share, and more.

Regional Scope

North America, Europe, Asia-Pacific, South America, Middle East & Africa

Country Scope

United States, Canada and Mexico, Germany, France, UK, Russia and Italy, China, Japan, Korea, India and Southeast Asia, Brazil, Argentina, Colombia etc.Saudi Arabia, UAE, Egypt, Nigeria and South Africa

Frequently Asked Questions (FAQ)

What is the size of the machine tools market in 2021?The machine tools market size was valued at US$ 76.84 billion in 2021.

What is the projected CAGR at which the machine tools market is expected to grow at?The machine tools market is expected to grow at a CAGR of 4.9% (2023-2032).

List the segments encompassed in this report on the machine tools market?Market.US has segmented the machine tools market by geography (North America, Europe, APAC, South America, and the Middle East and Africa). By type, this market has been segmented into Metal Cutting tools and Metal Forming. By technology, this market has been further divided into CNC and Conventional. By end-use, this market has been segmented into Automotive, Mechanical Engineering, Metal Working, Aerospace, Electrical industry, and Others.

List the key industry players in the machine tools market?DMG MORI, Doosan machine tools Co. Ltd., CHIRON Group SE, Hyundai Wia Corp., Georg Fischer Ltd., JTEKT Corporation, Okuma Corporation, Makino, and Komatsu Ltd., among Other Key Players.

Which region is more appealing for vendors employed in the machine tools market?APAC accounted for the highest revenue share of 42.6%. Therefore, the machine tools industry in APAC is expected to garner significant business opportunities over the forecast period.

Name the key areas of business for the machine tools market?The U.S., Canada, Mexico, Germany, France, Italy, Switzerland, etc. are key areas of operation for the machine tools Market.

Which segment accounts for the greatest market share in the machine tools industry?With respect to the machine tools industry, vendors can expect to leverage greater prospective business opportunities through the metal cutting type segment, as this area of interest accounts for the largest market share.

![Machine Tools Market Machine Tools Market]()

- DMG MORI

- Doosan machine tools Co. Ltd.

- CHIRON Group SE

- Hyundai Wia Corp.

- Georg Fischer Ltd.

- JTEKT Corporation

- Okuma Corporation

- Makino

- Komatsu Ltd.

- Other Key Players

- settingsSettings

Our Clients

|

Single User

$5,999

$2,999

USD / per unit

save 50% |

Multi User

$7,999

$3,499

USD / per unit

save 55% |

Corporate User

$12,999

$4,499

USD / per unit

save 65% | |

|---|---|---|---|

| e-Access | |||

| Data Set (Excel) | |||

| Company Profile Library Access | |||

| Interactive Dashboard | |||

| Free Custumization | No | up to 10 hrs work | up to 30 hrs work |

| Accessibility | 1 User | 2-5 User | Unlimited |

| Analyst Support | up to 20 hrs | up to 40 hrs | up to 50 hrs |

| Benefit | Up to 20% off on next purchase | Up to 25% off on next purchase | Up to 30% off on next purchase |

| Buy Now ($ 2,999) | Buy Now ($ 3,499) | Buy Now ($ 4,499) |