Global Pneumatic Conveying Systems Market By Operating principle (Dilute Phase Conveying, Dense Phase Conveying), By End-Use (Ceramic, Pharmaceuticals, Food, Rubber and Plastic, and Others), By Technology (Positive Pressure Systems, Vacuum Systems, Combination Systems), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2022-2032

- Published date: Apr 2022

- Report ID: 30434

- Number of Pages: 245

- Format:

- keyboard_arrow_up

Pneumatic Conveying Systems Market Overview:

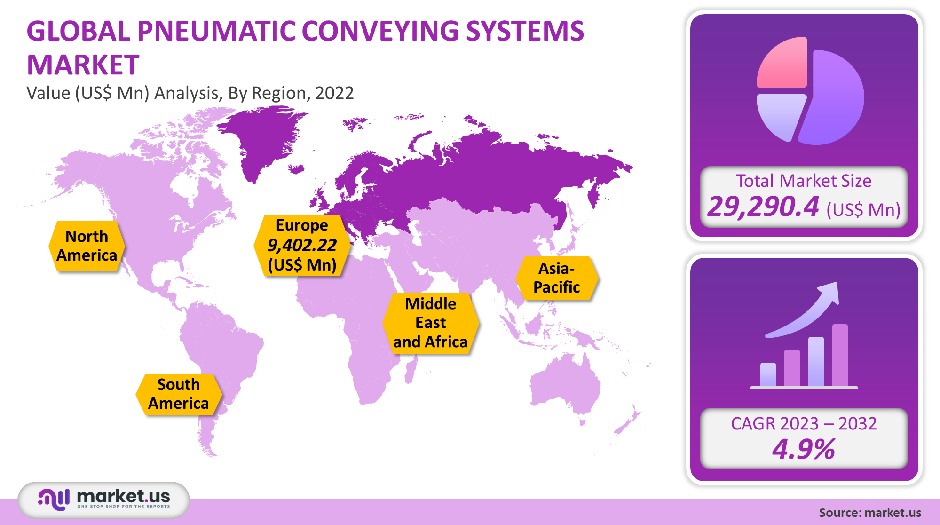

The market size for pneumatic conveying devices accounted for USD 29,290.42 million in 2021. It is expected that it will grow at a CAGR, of 4.9% from 2023-2032.

The market has gained momentum in recent years due to rising industrialization in emerging nations, increased recycling and waste treatment industry expansion, and growing demand for energy-efficient systems.

Global Pneumatic Conveying Systems Market Scope:

Operating Principle analysis

Based on the operating principle the market can be segmented into dilute and dense phases conveying. The dilute stage conveying segment had the largest share at over 72.8%, accounting for more than half of all revenue in 2021.

Based on the dilute operating principle, pneumatic conveying systems are expected to see significant growth. This is because these systems are commonly used for incessant conveying within certain industries that don’t have major concerns like dilapidation and/or abrasion. Low-density, nonfragile, and nonabrasive materials are best served by dilute-phase pneumatic conveyors. They are also very cost-effective and versatile. These are the reasons they are popular in high-pressure situations.

These systems can prevent the breakdown of fragile materials and mixtures by operating at low speeds and large air volumes. This makes them an indispensable part of many industries. These systems are expected to see high demand, which will lead to a rapid growth rate in the future.

Technology analysis

According to technology, the market for pneumatic conveying systems has been split into the vacuum, positive pressure, and combination systems. The market’s positive pressure segment was responsible for more than half the 2021 revenue. This can be attributed to positive pressure systems’ ability to operate at high pressures, which is a major advantage over other types. The market is expected to grow because they can transport heavy materials over long distances.

Vacuum systems are made up of high vacuum pumps which are easier to use and require less maintenance. Because it can use a vacuum system to place the material on the desired point in the stack, and also because it can transport materials from multiple sources to a single destination, this segment is expected to grow at 5.1%. They are composed of pressure systems that allow materials to be transported to multiple loading points at once and provide efficient conveying. This segment has seen rapid growth due to its ability to offer both vacuum systems and pressure systems.

End-Use analysis

Market segments can be categorized by end-use into pharmaceuticals, ceramic, food, rubber, plastic, cement, mining (mineral), and others. The 2021 total revenue was 29.5% for the food sector. Pneumatic conveyors have been gaining popularity due to their high reliability, increased production, lower risk of material being spilled, and low operating and maintenance costs.

Pneumatic systems will continue to be in high demand by the pharmaceutical sector. This is due to the high-risk nature of production and the need to deal with hazardous and risky materials. The mining industry is involved in the extraction of natural minerals such as ores and coke, oil, gas, liquid minerals, gases, and crude petroleum. These products are becoming more popular, which will, in turn, lead to an increase in demand for conveyors. This will in turn drive the market.

Кеу Маrkеt Ѕеgmеntѕ

By Operating Principle

- Dense Phase Conveying

- Dilute Phase Conveying

By Technology

- Vacuum Systems

- Combination Systems

- Positive Pressure Systems

By End-Use

- Rubber and Plastic

- Ceramic

- Cement

- Pharmaceuticals

- Mining (Mineral)

- Food

- Others

Market Dynamics:

Many manufacturers are now using automated pneumatic conveying equipment to protect their products from contamination. In addition, there are many technological developments in pneumatic conveyance that have resulted in increased adoption. These systems can also be equipped with advanced control technology. Also, the popularity of pneumatic conveying devices in material handling has been increasing, which will boost the market’s growth during the forecast period.

Pneumatic conveyors have many benefits. It can increase productivity, reduce production time, save costs, and improve quality in aspects like packaging, coating, or end products. These benefits have led many industries to adopt pneumatic conveyors. Conventional conveyors have a tendency to collect dust and foreign particles. This leads to material quality degradation and subsequent losses. This is why pneumatic conveyors are replacing traditional conveyors in some industries.

Product contamination is still a significant concern for end users. In order to keep up with increasing demand, industries like ceramics and food processing are spending a lot on pneumatic conveyors. The industry continues to face very competitive environments. Pneumatic conveyors can be installed to prevent losses and improve product quality. This is likely to increase the market’s growth.

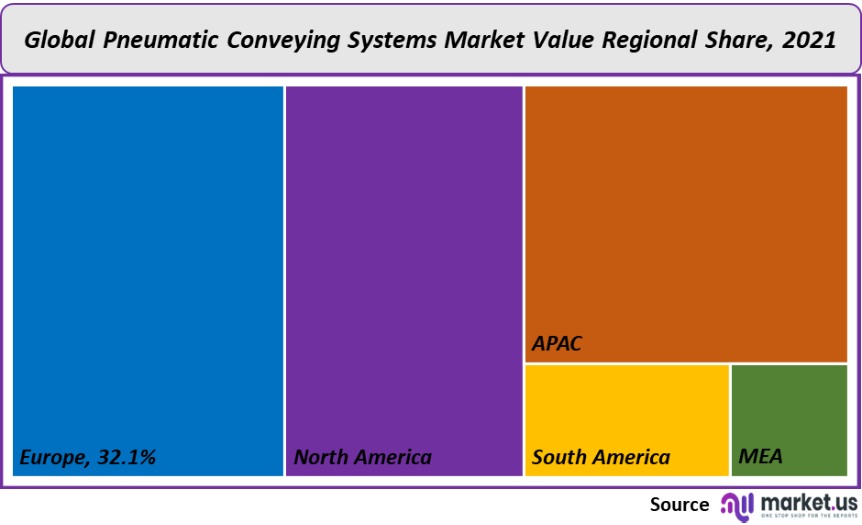

Regional Analysis

Europe accounted for more than 32.1% of total market revenue in 2021 and was the dominant market. Because of the growing demand for hygienic methods within the food transfer industry, the regional market is expected to experience significant growth in the future.

North America’s Food & Drug Administration has issued regulations concerning indirect contaminants in food. The region’s demand for pneumatic conveying equipment is expected to rise over the forecast period. The Asia Pacific region is seeing a rapid rise in the growth of the pharmaceutical sector. This will increase the demand for pneumatic conveying equipment.

In the region, there has been an increase in facilities that work on developing biosimilars and vaccines. This is especially true in developing countries. The governments of these countries are actively involved in promoting improved healthcare facilities and the development of associated industries. This situation is driving many pharmaceutical companies to move to emerge markets.

This shift in pharmaceutical manufacturing from developed to developing areas is likely to drive the demand for pneumatic conveying systems to APAC.

Key Regions and Countries covered іn thе rероrt:

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Russia

- Spain

- Rest of Europe

- APAC

- China

- Japan

- South Korea

- India

- Rest of Asia-Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- MEA

- GCC

- South Africa

- Israel

- Rest of MEA

Market Share & Key Players Analysis:

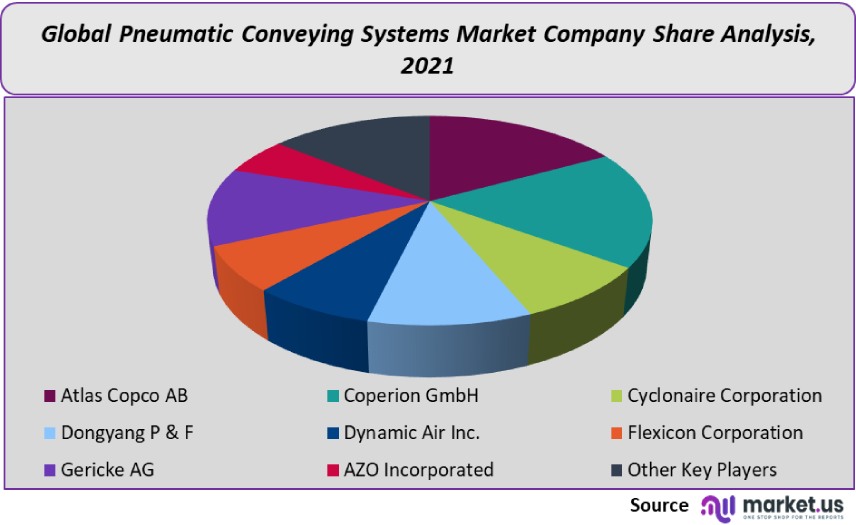

The vendor landscape is very consolidated and has high levels of competition. The market leaders are involved in mergers, acquisitions, and other activities to enhance their market positions. The top market players also focus on the development of new technologies to increase their competitive advantage. The following are some of the major players in the pneumatic conveying market:

Маrkеt Кеу Рlауеrѕ:

- Atlas Copco AB

- Coperion GmbH

- Cyclonaire Corporation

- Dongyang P & F

- Dynamic Air Inc.

- Flexicon Corporation

- Gericke AG

- AZO Incorporated

- Other Key Players

For the Pneumatic Conveying Systems Market research study, the following years have been considered to estimate the market size:

Attribute Report Details Historical Years

2016-2020

Base Year

2021

Estimated Year

2022

Short Term Projection Year

2028

Projected Year

2023

Long Term Projection Year

2032

Report Coverage

Competitive Landscape, Revenue analysis, Company Share Analysis, Manufacturers Analysis, Volume by Manufacturers, Key Segments, Key company analysis, Market Trends, Distribution Channel, Market Dynamics, COVID-19 Impact Analysis, strategy for existing players to grab maximum market share, and more.

Regional Scope

North America, Europe, Asia-Pacific, South America, Middle East & Africa

Country Scope

United States, Canada and Mexico, Germany, France, UK, Russia and Italy, China, Japan, Korea, India and Southeast Asia, Brazil, Argentina, Colombia etc.Saudi Arabia, UAE, Egypt, Nigeria and South Africa

Frequently Asked Questions (FAQ)

What is the size of the Pneumatic Conveying Systems market in 2021?The Pneumatic Conveying Systems market size is US$ 29,290.42million in 2021.

What is the projected CAGR at which the Pneumatic Conveying Systems market is expected to grow at?The Pneumatic Conveying Systems market is expected to grow at a CAGR of 4.9% (2023-2032).

List the segments encompassed in this report on the Pneumatic Conveying Systems market?Market.US has segmented the Pneumatic Conveying Systems market by geographic (North America, Europe, APAC, South America, and Middle East and Africa). By Operating Principle, market has been segmented into Dilute Phase Conveying, Dense Phase Conveying. By Technology, the market has been further divided into Positive Pressure Systems, Vacuum Systems, Combination Systems. By End-Use, the market has been further divided into Ceramic, Pharmaceuticals, Food, Rubber and Plastic, Cement, Mining (Mineral), Others.

List the key industry players of the Pneumatic Conveying Systems market?Atlas Copco AB, Coperion GmbH, Cyclonaire Corporation, Dongyang P & F, Dynamic Air Inc., Flexicon Corporation, Gericke AG, AZO Incorporated and Other Key Players engaged in the Pneumatic Conveying Systems market.

Which region is more appealing for vendors employed in the Pneumatic Conveying Systems market?Europe accounted for the highest revenue share of 32.1%. Therefore, the Pneumatic Conveying Systems industry in Europe is expected to garner significant business opportunities over the forecast period.

Name the key areas of business for Pneumatic Conveying Systems?France, Germany, Spain, Russia, The US, Canada, China and Others, are key areas of operation for Pneumatic Conveying Systems Market.

Which segment accounts for the greatest market share in the Pneumatic Conveying Systems industry?With respect to the Pneumatic Conveying Systems industry, vendors can expect to leverage greater prospective business opportunities through the Food Industry segment, as this area of interest accounts for the largest market share.

![Pneumatic Conveying Systems Market Pneumatic Conveying Systems Market]() Pneumatic Conveying Systems MarketPublished date: Apr 2022add_shopping_cartBuy Now get_appDownload Sample

Pneumatic Conveying Systems MarketPublished date: Apr 2022add_shopping_cartBuy Now get_appDownload Sample - Atlas Copco AB. Company Profile

- Coperion GmbH

- Cyclonaire Corporation

- Dongyang P & F

- Dynamic Air Inc.

- Flexicon Corporation

- Gericke AG

- AZO Incorporated

- Other Key Players

- settingsSettings

Our Clients

|

Single User

$5,999

$2,999

USD / per unit

save 50% |

Multi User

$7,999

$3,499

USD / per unit

save 55% |

Corporate User

$12,999

$4,499

USD / per unit

save 65% | |

|---|---|---|---|

| e-Access | |||

| Data Set (Excel) | |||

| Company Profile Library Access | |||

| Interactive Dashboard | |||

| Free Custumization | No | up to 10 hrs work | up to 30 hrs work |

| Accessibility | 1 User | 2-5 User | Unlimited |

| Analyst Support | up to 20 hrs | up to 40 hrs | up to 50 hrs |

| Benefit | Up to 20% off on next purchase | Up to 25% off on next purchase | Up to 30% off on next purchase |

| Buy Now ($ 2,999) | Buy Now ($ 3,499) | Buy Now ($ 4,499) |