Global Woven Sacks Market, by Product Type (Open Mouth Sack, Pinch Bottom Sack, Gusseted Sacks), by Material (Polypropylene (PP), High Density Polyethylene (HDPE)), and by End-Use Industry (Building & Construction, Agriculture, Chemicals, Food) and by Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2022-2032

- Published date: Feb 2022

- Report ID: 84646

- Number of Pages: 213

- Format:

- keyboard_arrow_up

Woven Sacks Market Overview:

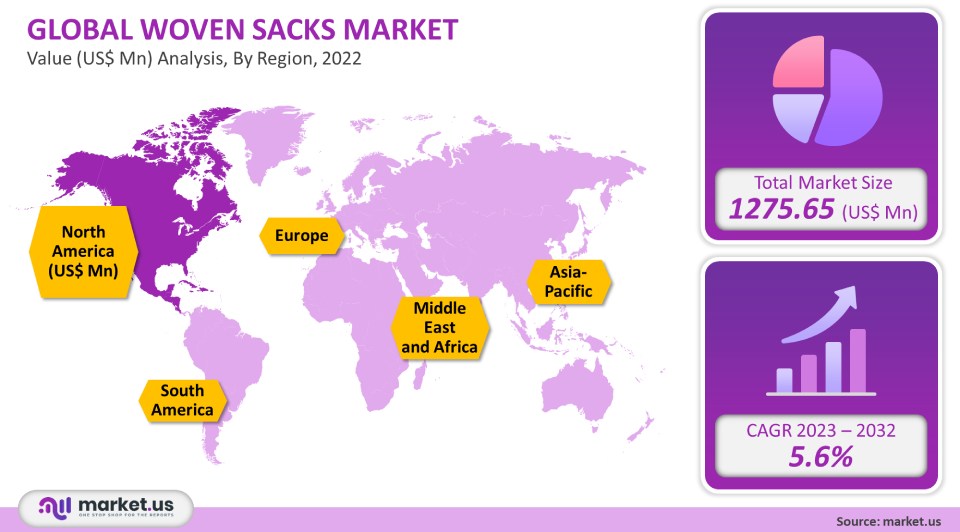

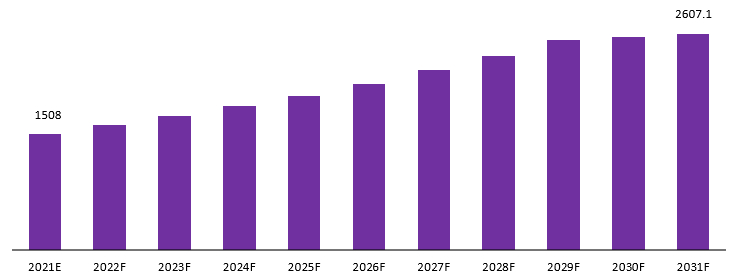

The global woven sacks market is projected to reach a valuation of USD 2199.73 Mn by 2031 at a CAGR of 5.6%, from USD 1275.65 Mn in 2021.

Plastic or polythene bags are not the only options for packing groceries, carrying books, or organizing an office. Reusable woven bags are a way to carry goods while promoting sustainable packaging or storage solutions.

Throughout history, woven sacks have been used as a common form of storage. Woven sacks are usually made up of non-toxic materials which are mainly anti-bacterial and are typically used to store either wheat or rice. These fabric sacks date back to the time of the ancient Egyptians when it was discovered that they were mainly used for food storage. At this time, woven sacks were made with sticks which created the stitching around the edges of the fabric. Woven sacks are a type of bag that is made out of fabric and has a cylindrical shape. This type of bag is generally used to carry various types of food or miscellaneous items and is commonly known as a “bread” sack as it can be found in certain grocery stores. They’re also called “sack bags”, as they’re often used to carry potatoes or other root vegetables.

Manufacturing woven bags is a very intricate process that first starts with making threads, weaving them into cloth, and then this cloth is used to make a bag. The first step in this process is to take cotton or linen thread and wind it around a spindle, which will twist the thread together to make yarn. Then, it is sent through a spinning machine to convert it from twisted threads too long strands of yarn. This yarn is used to weave the bag’s fabric. The weaving process is intricate and complex, going through a wide range of steps.

It begins with a loom, where a warp yarn is put down on a series of wooden or metal rods, oftentimes called a “loom beam”. A cross-piece usually called the “shuttle” then carries the weaver’s supply of yarn from one rod to the next as the weaver pushes it over with their hands. Bags are woven by hand or machine. They are typically made of natural fibers, such as cotton, jute, linen, burlap, and hemp. Most bags are woven on a loom that the weaver stands at while working. However, some weaving is done with horizontal looms where the weaver sits or kneels to work.

Traditional plastic grocery bags are non-biodegradable, meaning that they will exist in nature for centuries or longer. When they finally break down, they release harmful gases into the atmosphere that contribute to global warming. It’s obvious that consumers are more environmentally conscious than ever before. One of the best ways to make an eco-friendly choice when it comes to shopping is to choose a bag made from woven material, rather than a plastic one. A woven bag is stylish, long-lasting, and can be reused over again. The eco-friendliest woven bags are made with recycled material. A woven bag is more durable than a plastic bag but it requires extra care and maintenance. Woven bags made from recycled material are more durable because they are made with thread made from recycled plastic.

Global Woven Sacks Market Revenue (USD Mn), 2021–2031:

Market Dynamics:

They are lightweight, versatile, and cost-effective because they do not need extra fabric to cover them. This also makes them cheaper than their counterparts. The weave also makes it so that air can flow through the bag, making it breathable. Woven sacks are also water resistant, owing to the loose weave of the fabric. These sacks can be reused and machine washed without ruining its integrity. The qualities of a woven sack make it an excellent way to store and transport goods. The durability of the fabric and the strength of the stitching helps protect contents from harsh weather and rough handling. These heavy-duty sacks can withstand a wide range of conditions, and they’re lighter than canvas or other fabric types used for similar purposes. These factors are leading to an increase in their adoption, thereby fueling revenue growth prospects for this global industry.

Woven sacks are rapidly gaining popularity but they do have certain disadvantages such as, they act as carriers for germs and other disease-causing agents. Moreover, these sacks are not suitable for meat and vegetables as these foods are direct sources of bacteria. These factors may hamper this market to a certain extent.

There are now laws in place to ban the use of plastic bags in numerous areas. A woven bag is made from natural fibers like cotton or linen that can be used repeatedly. They are easy to carry, stylish, durable, and environmentally friendly. Factors such as these are expected t continue to create lucrative opportunities among existing as well as emerging players operating in this industry.

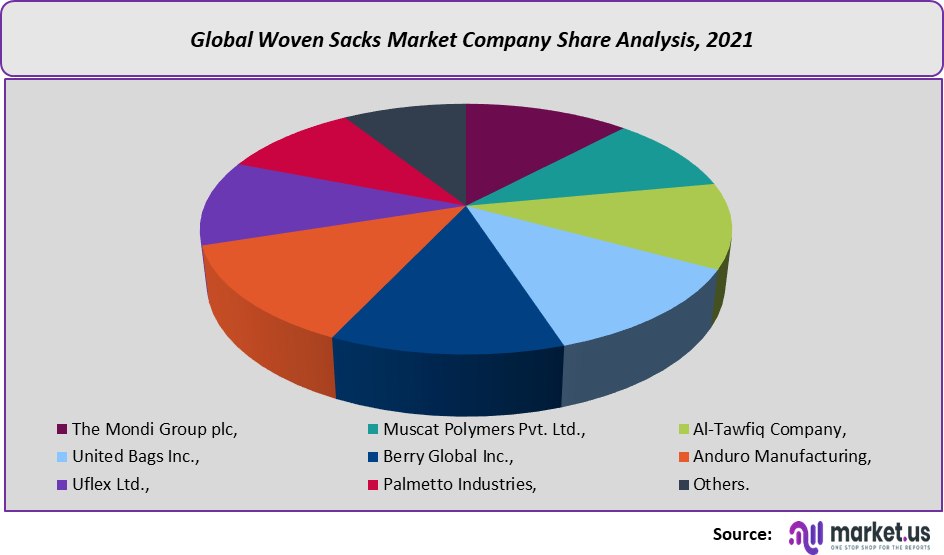

Competitive Landscapes:

This research report on the global woven sacks industry includes major company profiles such as

- The Mondi Group plc,

- Muscat Polymers Pvt. Ltd.,

- Al-Tawfiq Company,

- United Bags Inc.,

- Berry Global Inc.,

- Anduro Manufacturing,

- Uflex Ltd.,

- Palmetto Industries,

- Others.

Detail Segmentation:

Segmentation of Global Woven Sacks Market is Based on – Product Type, Material, End-Use Industry, and Region

Based on Product Type:

- Open Mouth Sacks

- Pinch Bottom Sacks

- Gusseted Sacks

- Valve Sacks

Based on Material:

- Polypropylene (PP)

- High-Density Polyethylene (HDPE)

Based On End-Use Industry:

- Building & Construction

- Agriculture

- Chemicals

- Food

- Other End-Use Industries

Based on Regions:

- North America

- Europe

- Asia Pacific

- South America

- MEA

For the Woven Sacks Market research study, the following years have been considered to estimate the market size:

Attribute Report Details Historical Years

2016-2020

Base Year

2021

Estimated Year

2022

Short Term Projection Year

2028

Projected Year

2023

Long Term Projection Year

2032

Report Coverage

Competitive Landscape, Revenue analysis, Company Share Analysis, Manufacturers Analysis, Volume by Manufacturers, Key Segments, Key company analysis, Market Trends, Distribution Channel, Market Dynamics, COVID-19 Impact Analysis, strategy for existing players to grab maximum market share, and more.

Regional Scope

North America, Europe, Asia-Pacific, South America, Middle East & Africa

Country Scope

United States, Canada and Mexico, Germany, France, UK, Russia and Italy, China, Japan, Korea, India and Southeast Asia, Brazil, Argentina, Colombia etc.Saudi Arabia, UAE, Egypt, Nigeria and South Africa

![Woven Sacks Market Woven Sacks Market]()

- The Mondi Group plc,

- Muscat Polymers Pvt. Ltd.,

- Al-Tawfiq Company,

- United Bags Inc.,

- Berry Global Inc.,

- Anduro Manufacturing,

- Uflex Ltd.,

- Palmetto Industries,

- Others.

- settingsSettings

Our Clients

|

Single User

$5,999

$2,999

USD / per unit

save 50% |

Multi User

$7,999

$3,499

USD / per unit

save 55% |

Corporate User

$12,999

$4,499

USD / per unit

save 65% | |

|---|---|---|---|

| e-Access | |||

| Data Set (Excel) | |||

| Company Profile Library Access | |||

| Interactive Dashboard | |||

| Free Custumization | No | up to 10 hrs work | up to 30 hrs work |

| Accessibility | 1 User | 2-5 User | Unlimited |

| Analyst Support | up to 20 hrs | up to 40 hrs | up to 50 hrs |

| Benefit | Up to 20% off on next purchase | Up to 25% off on next purchase | Up to 30% off on next purchase |

| Buy Now ($ 2,999) | Buy Now ($ 3,499) | Buy Now ($ 4,499) |